WRV Reducer

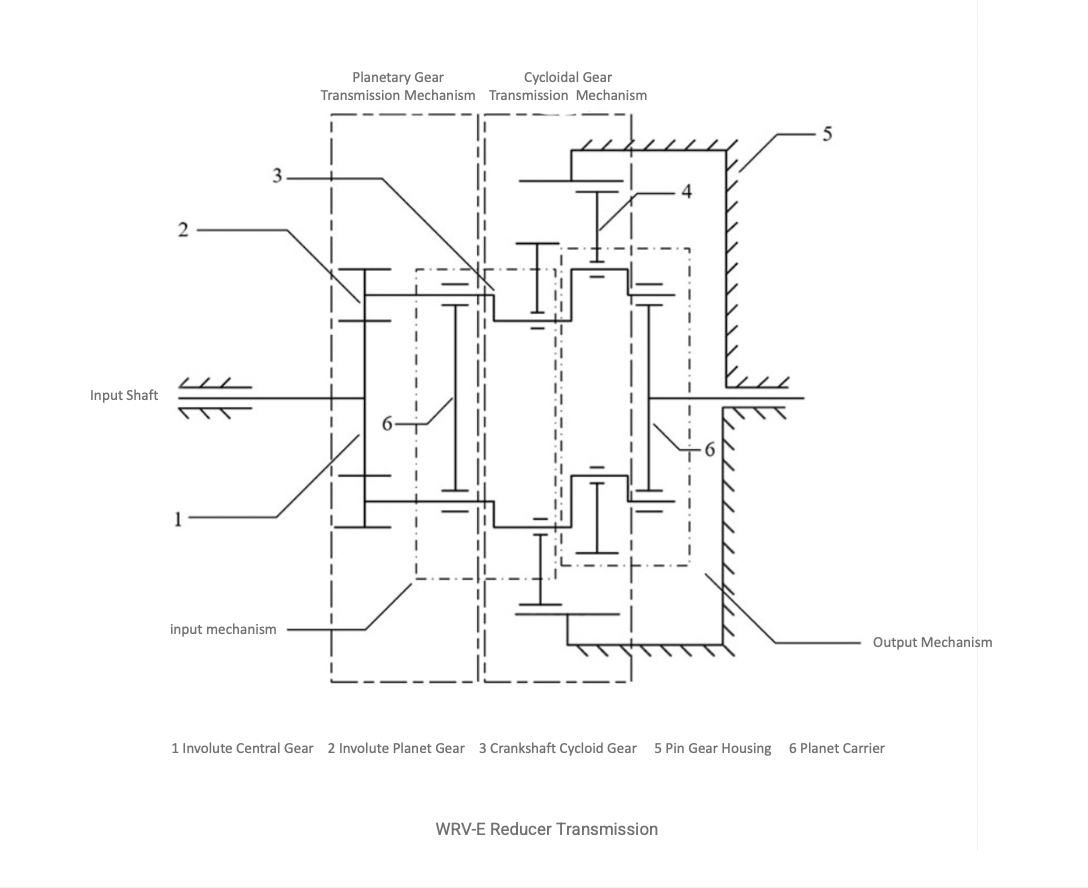

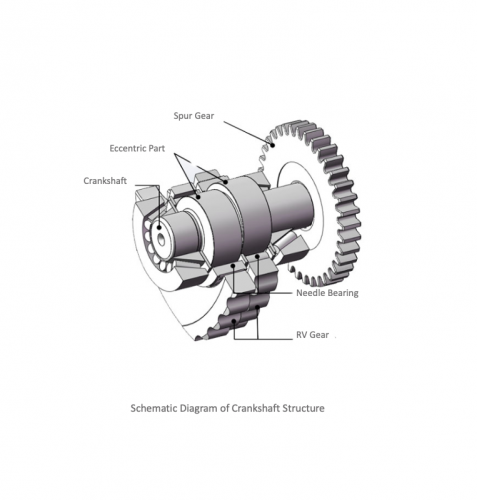

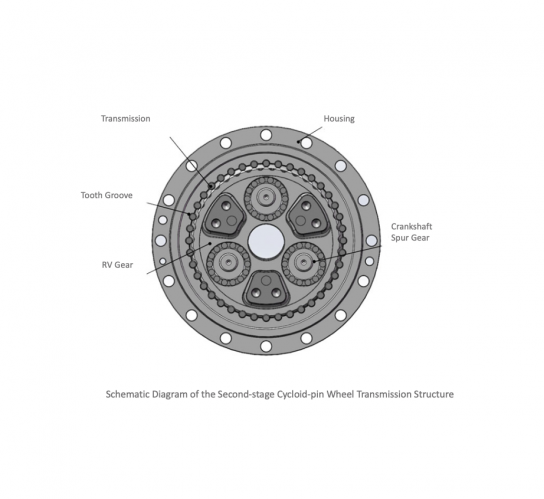

The RV reducer is a two-stage reducer, and the transmission principle is shown in Figure 1. The first-stage reduction mechanism is a planetary gear transmission mechanism, which transmits power from the center wheel to the planetary gears through the rotation of the input shaft, and decelerates according to the gear ratio; the second-stage reduction mechanism is a cycloid pin-wheel transmission mechanism, which is driven by the planetary gear to rotate The crankshaft drives the two cycloids for eccentric movement. The eccentric movement causes the cycloidal wheel to mesh with the pin tooth pin placed on the housing. The crankshaft rotates once, and the cycloid moves one needle tooth position in the opposite direction. When the reducer is driving, it has the characteristics of large number of meshing teeth, small gap, small vibration and inertia. It has the characteristics of small size, light weight, high rigidity, overload resistance, etc., which can ensure the smooth operation of the robot and achieve high transmission and positioning accuracy.

Core Advantage

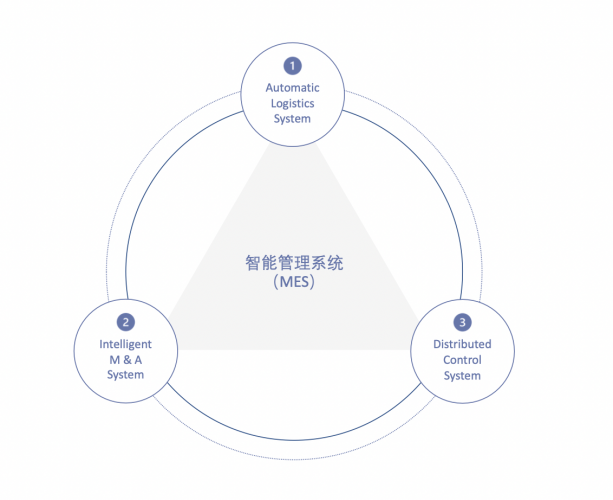

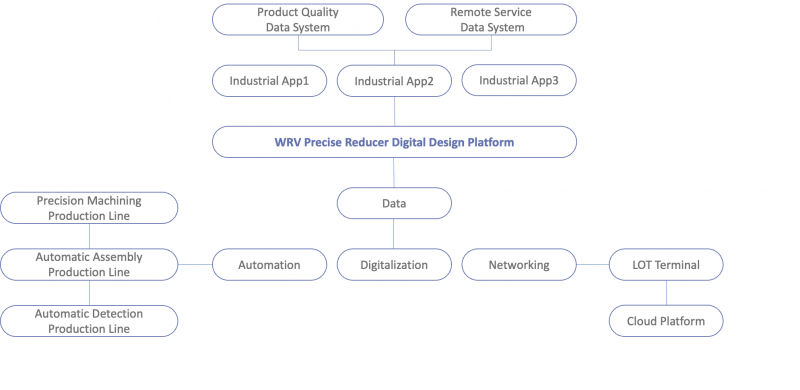

The WRV precision reducer design platform can realize the transmission design, force analysis, cycloid modification, bearing design, transmission error analysis and return analysis of the RV reducer. It can customize design and finally realize the platform. One-stop management, using a set of software and algorithm data to manage the full life cycle of the product.

Intelligent Production Line

Based on the concept of "Industry 4.0",we are committed to creating an automated production plant, automating the entire production process through robots and intelligent equipment.

Data Analysis System

Applied Area

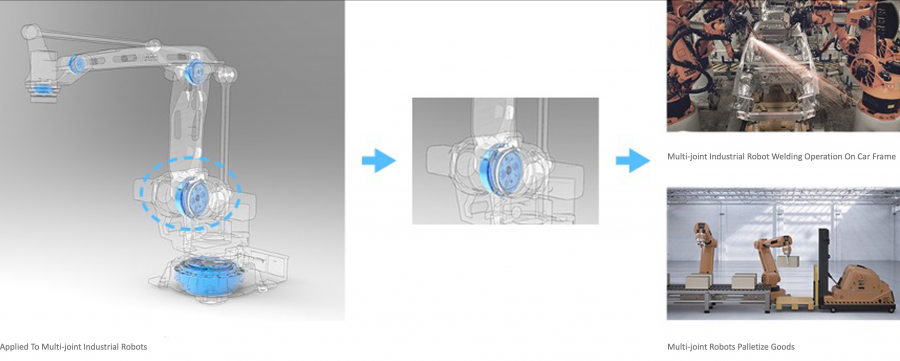

Applied to multi-joint industrial robotsRV reducer can be used in multi-joint industrial robots, such as automotive and machining industries. Specific functions include handling, welding, grinding, spraying, palletizing, loading, etc.

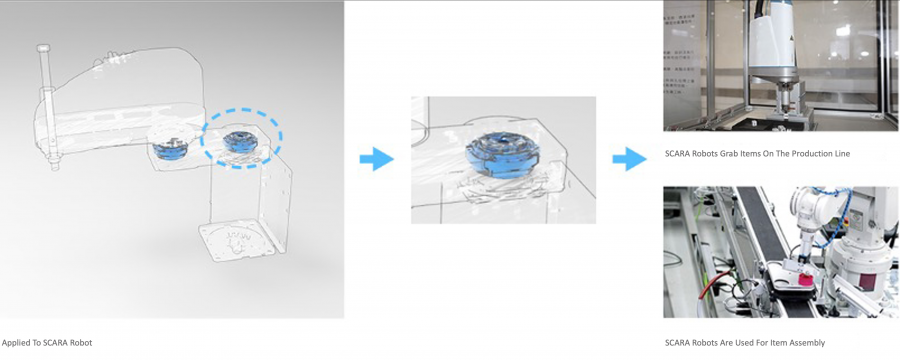

The RV reducer can be used in the rotating joints of SCARA robots. SCARA robots are mainly used in processes such as the grasping and assembly of parts in the 3C industry.

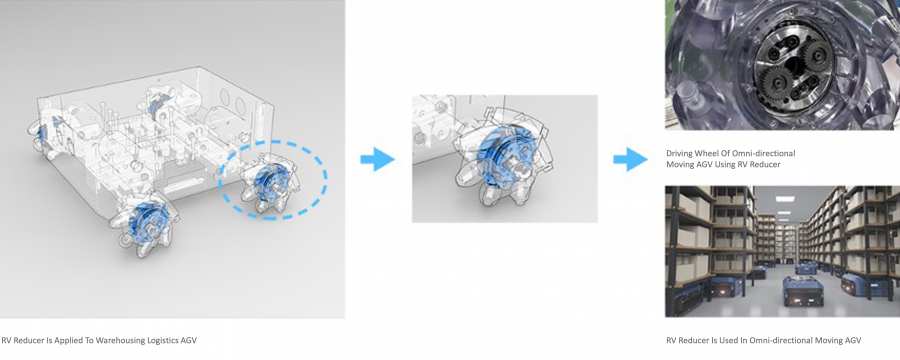

With the rapid development of the e-commerce industry, the business volume of the e-commerce warehousing and logistics industry has soared. At present, it is difficult for logistics practitioners to meet all the sorting and handling tasks of express parcels. In recent years, the intelligent sorting and handling of AVG has achieved unprecedented development in the field of warehousing and logistics. RV reducer has the advantages of compact structure, large reduction ratio and high transmission efficiency, and is suitable for some AGVs operating in narrow spaces.